The Basic Principles Of gearbox cvt

The Basic Principles Of gearbox cvt

Blog Article

Le Information de l'car est le place de repère par excellence du domaine auto au copyright. Il offre des nouvelles, des critiques et des vidéos exclusives ainsi que tous les détails sur les nouveaux véhicules et les véhicules d'occasion.

He is our resident van qualified, but addresses almost everything from scooters and motorbikes to supercars and client merchandise.

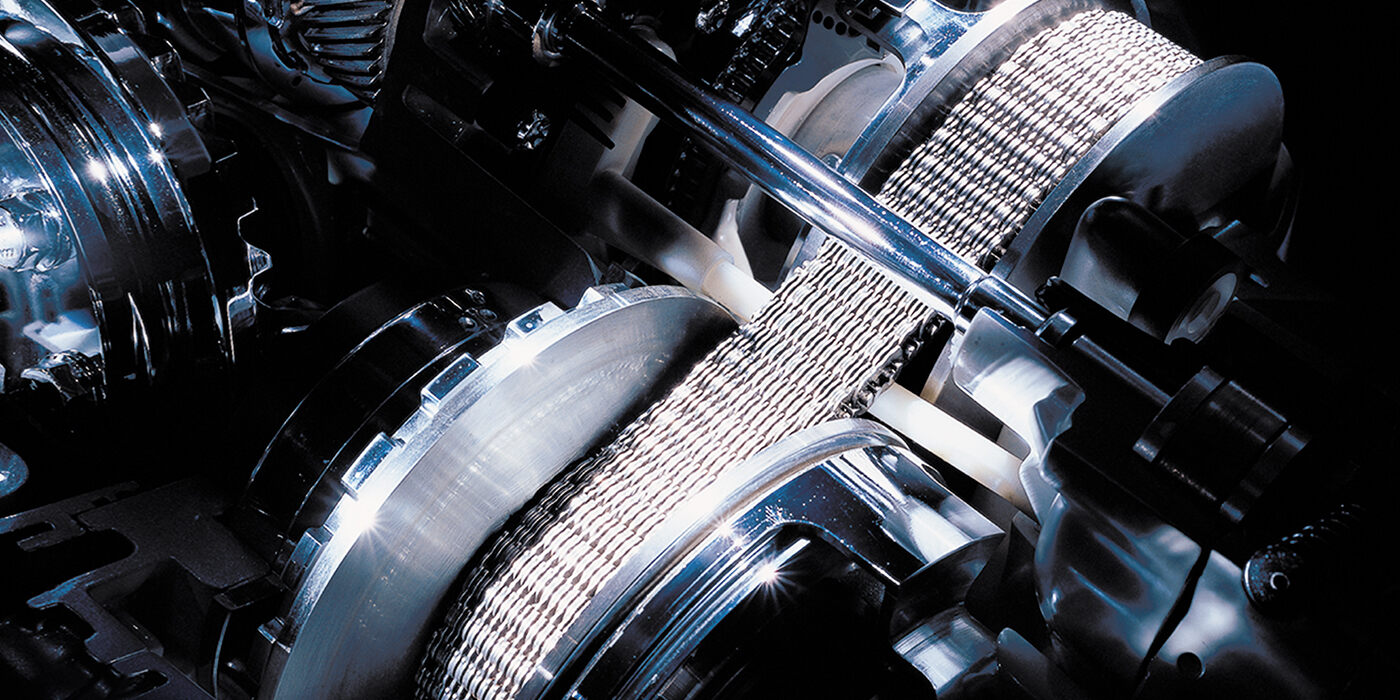

The pulley method in a CVT consists of two pulleys, just one connected to the motor and one other on the transmission. The two pulleys are related by a belt or chain. The pulleys are formed like cones, and their diameters can be altered to change the gear ratio.

Once i am stopped in a crimson gentle for an extended time period, is the “belt” struggling friction problems? Any aid you might be able to offer you are going to be appreciated.

You’ll know from driving that in leading equipment your motor only must do say 3000rpm for 100km/h – While 3000rpm in initially gear would see you only at about 25km/h.

In an epicyclic CVT (also known as a planetary CVT), the equipment ratio is shifted by tilting the axes of spherical rollers to provide distinctive Speak to radii, which consequently travel enter and output discs. This is similar in basic principle to toroidal CVTs. Generation versions include the NuVinci CVT.[28]

Inside of a hydrostatic CVT, the effective "equipment ratio" involving the motor as well as the driving wheel(s) is the result of a distinction between the pump's displacement—expressed as cubic inches or cubic centimeters for every revolution—along with the motor's displacement.

A lot of smaller cars—including snowmobiles, golf carts, and motor scooters—use CVTs, commonly on the cari di link ini pulley selection. CVTs in these automobiles often utilize a rubber belt by using a non-stretching set circumference manufactured working with numerous really tough and flexible products, a result of the mechanical simplicity and simplicity of use outweighing their comparative inefficiency.

A CVT works by using a belt connecting pulleys to produce a easy adjust in gear ratios. This set up allows for a gradual acceleration without the need of distinct gear shifts.

CVT transmissions may be much more fuel-economical than traditional transmissions since they can preserve the engine running at its most productive pace. However, this will vary based on the specific car or truck and driving problems.

He also likes to put in writing article content connected to the mechanical engineering field and attempts to encourage other mechanical engineering pupils by his modern project ideas, design, products and video clips.

it took me three months of consistent complaining but finally my CVT transmission dilemma was preset….. no more shudder/surge!

Some cone CVT designs use two rollers.[23][24] In 1903, William Evans and Paul Knauf utilized for your patent on a continually variable transmission employing two parallel conical rollers pointing in reverse Instructions and connected by belts that would be slid together the cones to differ the transmission ratio.

Some CVT designs even increase a “shift” feeling for those who speed up aggressively. The thought being that motorists may possibly want to come to feel the previous-school shifting feeling.